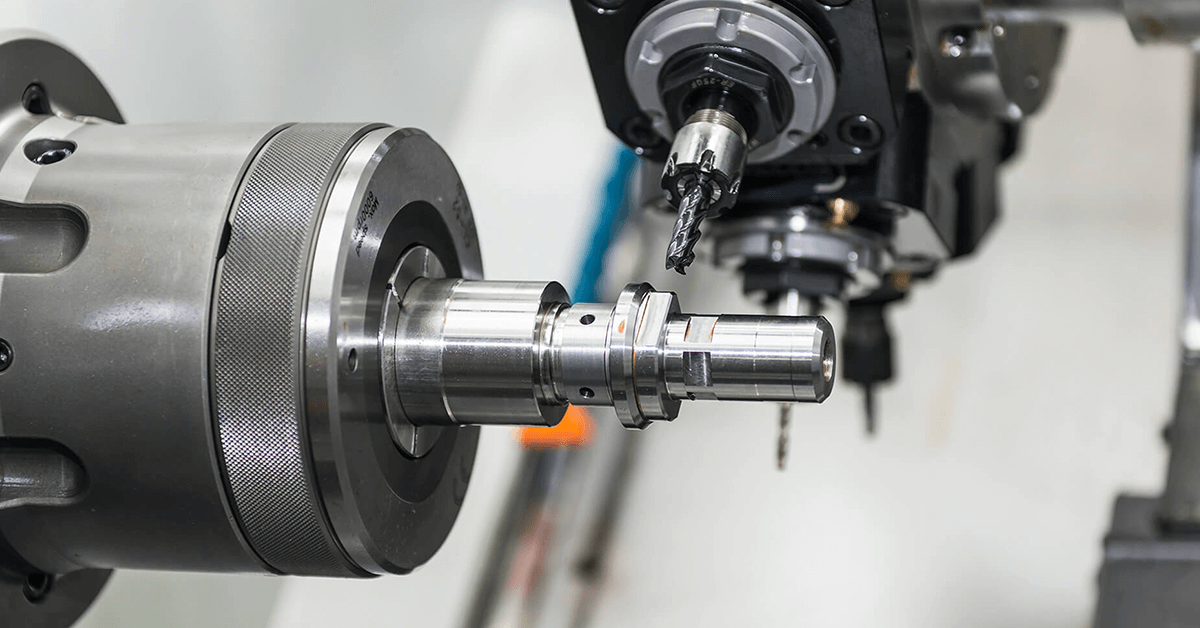

Subcontract CNC machining

In RADMOT we provide professional subcontarct CNC machining. We specialize in high volume production runs, adhering to tight tolerances using a diverse range of materials. Our precise machining and advanced CNC capabilities deliver cost-effective results, ensuring the highest standards in aerospace, automotive parts and medical devices manufacturing.

CNC contract manufacturing - What does

cooperation look like?

- 01 Enquiry

- 02 Quotation

- 03 Production

- 04 Quality

- 05 Advantages

- via the form on our enquiry page,

- by e-mail directly to rfq@radmot.com,

- by individual contact with our project managers in the sales department

We offer a fast, free quote. Do not hesitate. See for yourself.

We offer a comprehensive and professional service for CNC contract manufacturing of CNC turned parts and contract manufacturing of CNC milled parts as well as a range of additional services such as washing, assembly, anodising, laser marking, surface treatment or technical advice. We process aluminium, steel, copper, brass, plastics and other materials. With almost 40 years of experience, we offer CNC machining at the highest level.

After receiving a customer enquiry, our sales department team checks the possibilities of CNC contract machining. If the order meets our production conditions and business requirements - the best ratio of quality and service/price is achieved by the customer for production from 100 pieces/batch and 1,000 pieces/year - then we prepare an offer with a cost estimate.

Every project we take on is carefully analysed. We focus on the customer and their needs, because we know that every customer requires a customised and holistic approach. At this stage, we are supported in particular by a team of technologists who, thanks to their many years of experience, are able to identify the best machines for the job and develop ideal processing technologies for them. In addition, throughout the entire co-operation process, the customer can count on regular feedback from their account manager on the sales side, who will always keep them reliably informed about the status of CNC contract manufacturing.

Our machine park is equipped with more than 80 modern machines from renowned manufacturers, enabling us to offer our customers a wide range of different parts - from simple turned parts, where efficiency and process stability are important, to more complex and precise parts and the most demanding 5-axis simultaneous machining.

The advantages of a large machine park:

- Production flexibility: minimising the risk of non-delivery due to technical problems

- Optimised production technology: very good adaptation of the part to the machine tool

- Replaceability of machines (alternative technologies)

We own 22 measuring machines. We are certified to ISO 9001:2015, IATF 169494 and ISO 14001:2015 and are continuously working to improve our quality management system to ensure that our services are always provided at the highest level and in accordance with the required standards. We monitor the production process from the procurement of the material to the dispatch of the finished product to the customer.

Production is continuously monitored and batches are tested based on statistical modelling. At the customer's request, we can increase the frequency of measurements, which is sometimes justified for very complex details. We can guarantee a measurement accuracy of 0.005 mm.

We have a strong quality control team consisting of quality engineers and controllers who ensure the highest quality of production at every stage of the process:

- We achieve a controlled PPM rate (number of defective parts per 1 million units produced) of almost 0%.

- All complaints are recorded, analysed and processed on an ongoing basis.

Complaints are not repeated - we implement system measures to eliminate the possibility of operating errors. - We ensure effective control of manufactured parts - constant monitoring by the quality control department and high operator awareness as part of quality management.

- We have introduced the Procontrol system to statistically analyse production processes.

- We have a state-of-the-art machine park with more than 80 CNC machine tools and a team of 120 employees specialising in the production of complex parts for professional customers from many industries.

Each customer is supported by a sales department supervisor for the entire duration of the co-operation. We provide regular contact and feedback at every stage of the process. - We have dedicated teams for material procurement, technology and quality control, which ensure continuous optimisation of the production process and are ready to work with the customer to improve design and technology.

- We customise our offer to your needs and are supported by a dedicated team of technologists. We treat each project individually and holistically. We efficiently implement projects with up to several dozen references in a short time. We advise on the optimisation of parts.

- We specialise in demanding and technologically advanced projects.

- We are a preferred supplier for leading Polish and international companies for whom professionalism, stability and flexibility in production as well as the quality of the final product are important.

- We rely on our expertise developed over almost 40 years. We continuously improve and optimise our processes.

- We dynamically develop the company and our team.

What services does CNC contract manufacturing include?

CNC milling contract manufacturing

As an experienced manufacturer, we offer precision milled parts with maximum dimensions of 500 mm × 500 mm × 350 mm.

CNC milling contract manufacturing is carried out with great care using machine tools from renowned manufacturers, modern measuring equipment and professional CAM systems. CNC contract work is carried out professionally and efficiently by an experienced team for every project.

CNC turning contract manufacturing

A wide range of parts with diameters from 3 mm to 250 mm and a maximum length of up to 680 mm are produced with a view to cost-effectiveness. We take a professional approach to the selection of all production technology.

For CNC contract manufacturing, we carefully select the machine tool, the tools, the parameters and the product control plan. Statistical process control is fully integrated into the measuring machines.

They trusted us:

CNC contract manufacturing - get in touch with us!

We manufacture for globally active customers who set the world trends in their industries.

Through long-term partnerships, we can jointly set the standards in each such industry.

Find the most important information quickly!

Visit this section if you have any questions about the range of our services. We've provided answers to the most frequently asked questions to help you quickly assess our potential for collaboration. If you don't find the answer you're looking for here, check out our FAQ on Turning and Milling, or feel free to contact us directly!

What types of CNC machining services does Radmot offer under its subcontracting services?

Radmot offers a broad range of subcontract CNC machining services, including CNC milling and CNC turning. Our machine park is equipped with high-quality machining centers that are capable of processing a range of materials including metals such as aluminium, steel, copper, brass, and plastics. We tailor our services to meet individual client needs, enabling us to realize even the most advanced projects. Our team of CNC operators and specialists bring their expertise and years of experience to each project, ensuring we provide the best possible support throughout the completion of the project.

Does RADMOT allow for a trial run before starting full-scale subcontract CNC production to ensure specific client requirements are met?

Yes, Radmot provides the option of conducting a trial run before commencing full-scale subcontract CNC production. This is a critical step towards ensuring the highest quality and guaranteeing that all client requirements are fully met. As a subcontract CNC machining service provider, we understand the significance of this process as it allows for any necessary optimizations in the manufacturing process. This ensures that the final product accurately meets the client's expectations and adheres to the technical documentation.

What are the maximum dimensions of parts that can be CNC machined in RADMOT?

RADMOT’s CNC machining capabilities allow for the production of parts with maximum dimensions of 500 x 500 x 350 mm for CNC milling and a diameter of up to 250 mm with a length of 680 mm for turning. These parameters enable us to manufacture a wide range of parts for various sectors, from small, precise components to larger elements, whilst maintaining high precision and tight tolerances.

What quality certificates does Radmot hold for its CNC machining services?

CNC machining plant RADMOT holds several quality certifications for its subcontract CNC machining services, including ISO 9001:2015, IATF 16949, and ISO 14001:2015. These certifications attest to our ability to produce high-quality CNC machine parts, adhering to international standards and industry expectations. They serve as proof of our commitment to maintaining the highest quality standards and continuously improving our manufacturing process.

What is the minimum order quantity for CNC milling and turning at RADMOT?

At RADMOT, the minimum order quantity for subcontract CNC machining services varies for CNC milling and turning. For CNC milling, the minimum order is 100 parts, assuming a contracted volume of 500 pieces per year. For CNC turning, the minimum order quantity is 250 pieces, with a contracted volume of 1000 pieces per year. This allows us to provide cost-effective production runs for our clients, whether they require high-volume production or more precise machining for smaller orders.

Does RADMOT provide any surface finish treatments or additional processing for the parts produced under subcontract CNC machining?

Yes, RADMOT offers a range of additional services beyond just manufacturing parts through subcontract CNC machining. This includes various surface finish treatments such as anodizing, galvanizing, impregnation with elements, and powder coating. We understand that for many parts, especially those used in industries like aerospace, automotive, and medical devices, the surface finish can be critical to function. Therefore, we aim to provide these services to ensure our parts meet the exact requirements of our clients. Additionally, we also offer ultrasonic cleaning and laser marking services to deliver ready-to-use parts that meet both functional and aesthetic needs.

Find out what else we can offer your company

As a CNC company, we have extensive experience in the manufacture of mechanical parts for a wide range of industries.

CNC Milled parts

CNC milling 3-axis / 4-axis / 5-axis indexing and simultaneous with maximum dimensions of 500 x 500 x 350 m.

Milling of solid material, machining of profiles, castings, forgings. Production batch size: from 100 pieces.

CNC Turned parts

CNC turning of forgings and castings with a maximum diameter of 250 mm.

Automatic turning of parts with a maximum diameter of 65 mm, shaft turning, production of turned and milled parts. Production batch size from 250 pieces.