CNC Services

Turning, Milling

& Anodising

We offer high precision CNC services tailored especially for complex parts with high requirements. We machined aluminium, steel, copper, brass, plastics and other materials. The best ratio of the service quality level to the price can be obtained with the production volume starting from 100 units per series and 1,000 units per annum.

experience

machine tools

employees

each day

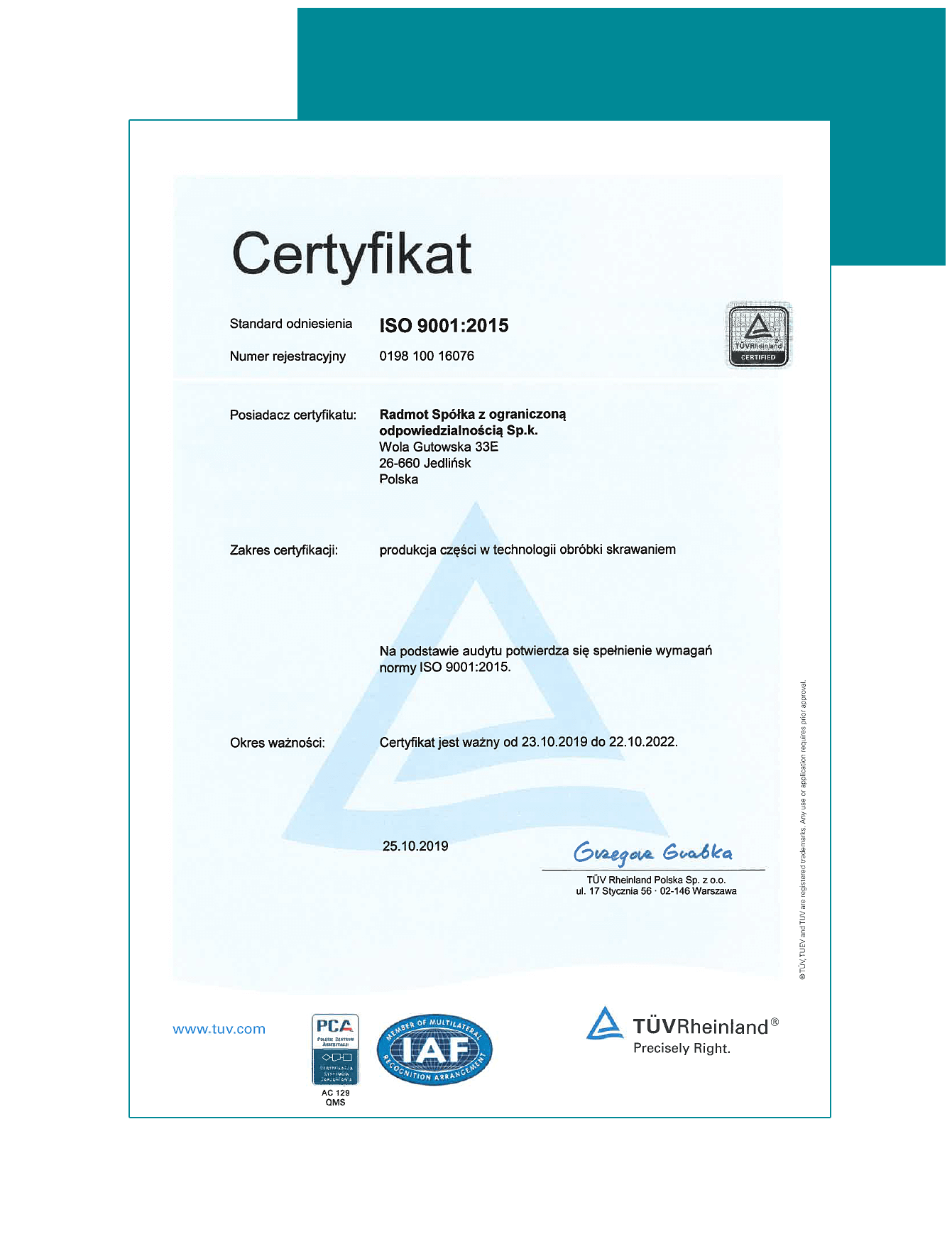

We have 40 years of experience in CNC services. Our state-of-the-art machinery park, experienced personnel, work based upon quality management systems ISO 9001:2015, IATF 16949, ISO 14001:2015, and knowledge of requirements put forward Customers from many manufacturing branches makes it possible for us to carry out advanced turning and milling services for plentiful companies.

Join the group of satisfied customers:

Rely on our precision and scale

As a leader in high-precision machining, we offer the highest level CNC services. We are concentrating on high volume production, but still we are very effecitive with smaller batches. The best way to start is to consult our Project Managers and find out the details.

CNC milled parts

3-axis / 4-axis / 5-axis indexial and simultaneous CNC milling with the maximum dimensions of 500 x 500 x 350 m.

Milling of solid material, treatment of profiles, castings, forgings. Our production lot size starts from 100 units.

We machine:

✓ Aluminium

✓ Bronze

✓ Copper alloys

✓ Carbon steel

✓ Alloy steel

✓ Stainless steel

✓ Brass

✓ Plastics and acrylics

✓ Titanium

*Other materials are subject to individual consideration

We also offer:

Chemical and electrochemical treatment

- Soft anodising (12 colours)- Hard anodising

- SurTec 650

- Electropolishing

- Passivation

- Chromating

- Blackening

- Galvanic zinc plating

- Nickel plating

- Chrome plating

- Silver plating

- Gilding

Mechanical surface treatment

- Glass bead blasting

- Brushing

- Polishing

- Special satin finishing

Heat treatment

- Hardening

- Normalising

- Carbonitriding

Powder coating

Painting

Laser marking

Surface cleaning and preparation, and packaging

- Ultrasonic cleaning

- Assembly

- Packaging

*Additional finishing options available on request.

SECTORS

Examples of industries we serve:

How are we evaluated by our Customers?

DOWNLOAD THE PDF

Choose machinery park with more than 80 state-of-the-art machine tools made by world-renowned manufacturers.

It is possible to select a perfect machine for a given part and quantity in order to provide for competitive price, all as a part of our precision CNC services.

Send an enquiry and discover our capabilities

We will respond to your enquiry within 24 hours.

Quickly find the most important information!

Check this section if you have questions about the scope of our services. We have prepared answers to the most frequently asked questions to help you quickly assess our potential for collaboration. If you don't find the answer you're looking for here, also check the Turning FAQ and Milling FAQ sections or simply contact us!

What materials do Radmot's CNC services cover?

You can commission CNC services from us for materials such as:

- Aluminum- Stainless steel

- Structural steel

- Carbon steel

- Brass

- Copper

- Bronze

For plastic materials, we offer CNC services for:

- Polyoxymethylene (POM)- Polyamide (PA)

- Polyethylene (PE)

- Polyvinyl chloride (PVC)

- Polypropylene (PP)

- Polytetrafluoroethylene (PTFE)

- Polycarbonate (PC)

- Polyetheretherketone (PEEK)

and more.

We select the turning or milling method and technology individually for each material, considering cost optimization, functionality, and tolerance requirements for the specific component.

Can I order CNC services for individual components, or only for production runs?

The size of our company translates to the scale of orders we accept:

- Minimum order quantity for CNC milling services: from 100 pcs / batch for 500 pcs / annually.

- Minimum order quantity for CNC turning services: from 250 pcs / batch for 1000 pcs / annually.

However, this does not exclude the possibility of providing CNC services for smaller test batches or executing individual trials. We encourage you to contact us to present your full expectations regarding collaboration, as we evaluate each inquiry individually.

Do you produce trial batches?

Yes. After placing an order, we can conduct production of a trial batch upon request and at the customer's expense. We do not specify minimums or maximums for the size of the trial batch. We encourage customers to use this option because it allows for mutual revision of expectations, review of the adopted technology, and thus effective optimization of the project, especially if we are commencing long-term cooperation in the field of CNC services.

What are the maximum dimensions of parts you can manufacture?

Our specialization and market distinction lie in the production of precision parts, which are generally small by definition. Nevertheless, the work areas of our machines are as follows:

- for milled parts: 500 x 500 x 350 mm

- for turned parts: diameter ⌀ 6 - 250 mm, length: 250

An additional consideration is the weight of the material to be machined. The technological assessment of incoming orders is always carried out by the Technology Department, and if you have any doubts, it is always better to take advantage of our free consultation.

What are the minimum tolerances of parts you can meet?

We accept orders for CNC machining even in the 6th class of accuracy for turned parts and in the 7th class for milled parts. We ensure this primarily through constant investments in the best CNC machines on the market (Hermle, Okuma, Doosan, DMG) and the quality of cutting tools. This is complemented by maintaining an extensive Quality Assurance Department operating in 4 laboratories equipped with measuring tools of the appropriate class, including:

- roundness gauges for measuring narrow geometric tolerances,- coordinate measuring machines,

- optical measurement systems.

What files should be prepared when requesting a quote for CNC services?

To allow us to quickly respond to your inquiry, send us:

- a technical drawing of the component (PDF or other graphic file)- 3D Model (we prefer .step, .stp, .x_t, .x_b files)

Of course, don't forget to provide us with all other order parameters such as: material type, batch size, annual quantity, tolerance, packaging method, delivery method, and any other additional requirements.

Does the company offer additional services such as anodizing or assembly of finished parts?

We understand the logistical importance of comprehensive order processing. Therefore, in addition to CNC turning and milling, we have prepared our plant to provide a wide range of additional services such as:

- aluminum anodizing- parts cleaning (including ultrasonic cleaner)

- part assembly

- laser marking (including serial numbers)

- electropolishing

- glass bead blasting

- other surface treatments

Furthermore, if we manufacture a particular part, we can provide additional processes such as passivation, zinc plating, phosphating, nickel plating, silver plating, or hardening.

Set your industry trends together with us

Write to us and get a free quote on CNC services.